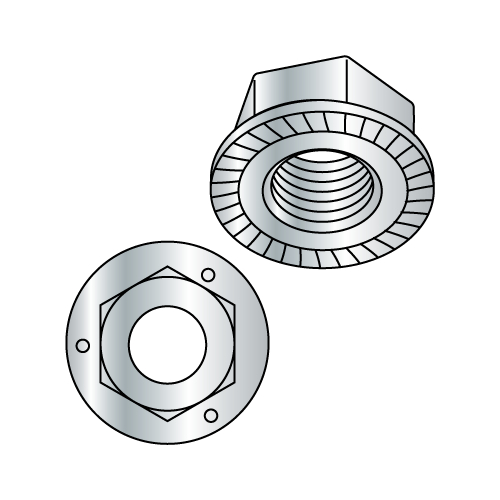

Nuts Flange

Nuts flange minangka jinis nut sing nampilake flange sing amba ing siji mburi. Flange nyedhiyakake permukaan sing luwih gedhe, nyebarake beban lan nyuda risiko ngrusak permukaan sing diikat.

-

Nuts Flange Serat Stainless SteelDetailTabel dimensi

Ayainox nawakake baja flange stainless steel grapyak minangka bagean saka barisan produk, nyedhiyakake solusi cepet kanggo macem-macem kualitas kanggo macem-macem aplikasi industri. AyeinOX Flange Flange nampilake para penderensi sing dirancang presisioned ing sisih ngisor saka flange, nyedhiyakake genggeman lan resistensi sing apik kanggo ngeculake nalika kena geter utawa torsi.

Kita nawakake macem-macem ukuran ukuran lan pitches kanggo ngrampungake macem-macem bolt utawa ukuran size lan spesifikasi, rapat karo kabutuhan macem-macem proyek lan aplikasi.Thread Screw

dM5 M6 M8 M10 M12 (M14) M16 M20 P Pitch 0,8 1 1.25 1.5 1.75 2 2 2,5 c min 1 1.1 1.2 1.5 1.8 2.1 2.4 3 da Max 5.75 6.75 8.75 10.8 13 15.1 17.3 21.6 min 5 6 8 10 12 14 16 20 dc Max 11.8 14.2 17.9 21.8 26 29.9 34.5 42.8 dw min 9.8 12.2 15.8 19.6 23.8 27.6 31.9 39,9 e min 8.79 11.05 14.38 16.64 20.03 23.36 26.75 32.95 m Max 5 6 8 10 12 14 16 20 min 4.7 5.7 7.64 9.64 11.57 13.3 15.3 18.7 mw min 2,5 3.1 4.6 5.6 6.8 7.7 8.9 10.7 s Max 8 10 13 15 18 21 24 30 min 7.78 9.78 12.73 14,73 17.73 20.67 23.67 29.16 r Max 0,3 0,4 0,5 0,6 0,7 0.9 1 1.2 -

Nut flange stainlessDetailTabel dimensi

Ayainox ngasilake kacang-tahan flange stainless steel, sing dadi pengikat khusus kanthi flang (luwih akeh bagean rata) Integrasi menyang desain nut. Umumé digawe saka bahan baja tahan karat, kayata kelas 304 utawa 316 stainless steel, nawakake resistensi korosi lan daya tahan sing apik. Dheweke nemokake aplikasi ing macem-macem industri, kalebu otomotif, konstruksi, larangan, lan mesin.

Nalika nimbang-nimbang-nimbang-nimbang flange hiasan atian kanggo proyek sampeyan, sampeyan bisa nyana kinerja, daya tahan, lan keahlian sing dipercaya ing macem-macem aplikasi sing mbutuhake solusi sing kuwat lan getaran.

Nominal

UkuranDiameter utama utama benang Lebar ing Flat, F Lebar ing sudhut, g Diameteripun flange, b Kekandelan nut, h Dawane length minimum, j Kekandelan flange minimal, k Runout maksimal saka learing learing menyang benang sumbu, fim Min. Max. Min. Max. Min. Max. Min. Max. Hex Flange Nuts No.6 0.1380 0,302 0,312 0.342 0.361 0.406 0.422 0.156 0.171 0,10 0,02 0,014 8 0.1640 0.334 0.334 0.381 0.397 0.452 0.469 0.187 0.203 0.13 0,02 0,016 10 0.1900 0.365 0.375 0.416 0.433 0.480 0.500 0.203 0.219 0.13 0,03 0,017 12 0,2160 0.428 0.438 0.488 0,505 0.574 0.594 0,222 0.236 0.14 0,04 0,020 1/4 0,2500 0.428 0.438 0.488 0,505 0.574 0.594 0,222 0.236 0.14 0,04 0,020 5/16 0.3125 0.489 0.500 0.557 0.577 0,660 0,680 0.268 0.283 0.17 0,04 0.023 3/8 0.3750 0.551 0.562 0,628 0,650 0,728 0.750 0.330 0.347 0.23 0,04 0,025 7/16 0.4375 0,675 0,688 0.768 0.794 0,910 0.937 0.375 0.395 0,26 0,04 0,032 1/2 0.5000 0.736 0.750 0,840 0.866 1.000 1.031 0.437 0.458 0.31 0,05 0,035 9/16 0.5625 0.861 0.875 0.982 1.010 1.155 1.188 0.483 0,506 0.35 0,05 0,040 5/8 0,6250 0.922 0.938 1.051 1.083 1.248 1.281 0.545 0.569 0,40 0,05 0,044 3/4 0.7500 1.088 1.125 1.240 1.299 1.460 1.500 0,627 0,675 0.46 0,06 0,051 Kacang flange gedhe hex 1/4 0,2500 0.428 0.438 0.488 0,505 0.700 0,728 0.281 0,312 0.15 0,04 0,024 5/16 0.3125 0.489 0.500 0.557 0.577 0.790 0.820 0.343 0.375 0,20 0,04 0,028 3/8 0.3750 0.551 0.562 0,628 0,650 0.885 0.915 0.390 0.406 0,24 0,04 0,031 7/16 0.4375 0,675 0,688 0.768 0.794 1.100 1.131 0.437 0.468 0,26 0,04 0,038 1/2 0.5000 0.736 0.750 0,840 0.866 1.175 1.205 0,485 0.515 0,29 0,06 0,041 9/16 0.5625 0.861 0.875 0.982 1.010 1.260 1.300 0.546 0.578 0.37 0,06 0,044 5/8 0,6250 0.922 0.938 1.051 1.083 1.280 1.360 0.600 0,640 0.42 0,06 0,045 -

Kacang Flange Stainless SteelDetailTabel dimensi

Kacang flange baja stainless steel minangka pengikat khusus kanthi flange terintegrasi ing siji mburi. Flange iki nyedhiyakake sawetara mupangat, kalebu nyebarake beban sing luwih gedhe, nyegah karusakan ing materi sing diikat, lan tumindak minangka mesin cuci sing dibangun kanggo nglindhungi permukaan.

Ukuran Utas M5 M6 M8 M10 M12 M14 M16 M20 D P Pitch Benang kasar 0,8 1 1.25 1.5 1.75 2 2 2,5 Benang 1 / / 1 1.25 1.5 1.5 1.5 1.5 Benang 2 / / / -1 -1.25 / / / c min 1 1.1 1.2 1.5 1.8 2.1 2.4 3 da min 5 6 8 10 12 14 16 20 Max 5.75 6.75 8.75 10.8 13 15.1 17.3 21.6 dc Max 11.8 14.2 17.9 21.8 26 29.9 34.5 42.8 dw min 9.8 12.2 15.8 19.6 23.8 27.6 31.9 39,9 e min 8.79 11.05 14.38 16.64 20.03 23.36 26.75 32.95 m Max 5 6 8 10 12 14 16 20 min 4.7 5.7 7.6 9.6 11.6 13.3 15.3 18.9 mw min 2.2 3.1 4.5 5.5 6.7 7.8 9 11.1 s maksude = ukuran nominal 8 10 13 15 18 21 24 30 min 7.78 9.78 12.73 14,73 17.73 20.67 23.67 29,67 r Max 0,3 0.36 0.48 0,6 0,72 0,88 0.96 1.2